I.Background introduction

In the electronic product manufacturing industry, it is often necessary to test whether the chemical substances attached to the product generate toxic and polluting gas under high temperature environments and certain pressure conditions, which harm human health. It is necessary to take the product into a closed high-temperature box for heating experiment (generally within 100°C), then extract the gas generated in the closed high-temperature box for testing, and then return the gas to the original high-temperature box to continue heating after testing. In such a closed loop air circuit, a micro vacuum is needed to act as the power source for the air flow. For example: production and inspection of multilayer flexible boards, flexible circuit board substrates, protective films and other fields.

II. Applicaiton

When users use the closed circulation gas circuit mechanism to detect gas content, they all use micro gas pumps to promote the flow of gas medium in the pipeline. Because of its small size, low power consumption, convenient control and connection, the miniature air pump isfavored by many experimental workers. The micro air pump has a significant effect in the process of adjusting precise small flow and small pressure. However, many of the miniature air pumps on the market now have a single function, a short life, and can only extract normal temperature medium, and the performance is far from meeting the user's requirements. The miniature vacuum pump developed and produced by Chengdu Hilin Technology has a variety of speed control methods to choose from in terms of control functions, and users can choose according to their actual applications. For customer needs for pumping high-temperature medium gas (50~100℃), we have specially launched a customized high-temperature medium micro vacuum pump to meet the needs of different customers.

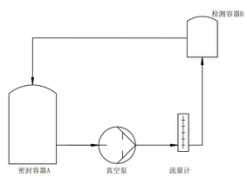

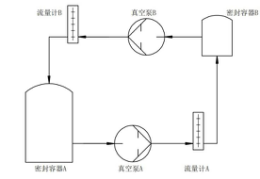

In addition, in some closed circulating gas circuits, the closed high-temperature reaction vessel A has a certain positive pressure. When the micropump pumps air from container A to another container B for testing, the internal pressure of container A will decrease, and because of the damping factor of the air path, the pressure and flow from container B back to the original container A are attenuated. The pressure conditions under which the product in container A reacts. In order to ensure that the pressure in vessel A is constant, a micro vacuum pump of the same version can be added to the air inlet of vessel A, and the same electrical signal is input to the two micro vacuum pumps to operate. When the air outlet of vessel A is pumped, the internal pressure is reduced, and the inlet can be supplemented with the same flow of gas. (If there is no requirement for the pressure parameter conditions during the use of the closed circulation gas circuit, then use the scheme shown in Figure 1 below, and if there are requirements for the pressure parameters, use the scheme shown in Figure 2 below)

图1

图2

III. Project Difficulties

1. High-temperature gas medium needs to be extracted on site. The temperature of the medium ranges from 70-90°C. The general miniature vacuum pumps cannot meet the conditions.2. The user tests multiple sets of data and needs to adjust the flow rate of the micropump repeatedly. It is better if it’s easy to operate and can intuitively reflect the running state of the pump.

3. During the detection of gas extraction in the closed circulating gas path, the positive pressure value in the closed reaction vessel needs to be kept constant, and the pressure conditions required for the experiment will not be destroyed due to the gas being pumped out of the closed reaction vessel. And the gas flow rate of the inlet and outlet is similar.

IV. Solution

1. The micro vacuum pump developed by Hilin Technology is suitable for pumping high temperature medium on site. Within the temperature range of 50~100℃, high temperature medium micro vacuum pump can be customized.

2. In order to make it easier for users to operate and observe,Hilin Technology specially developed a vacuum pump with touch display function. You can directly adjust the pump by touching the "+" or "-" on the display with your finger. Speed, and the running speed status of the pump can be viewed directly on the display. When the air pump stops or an abnormal situation occurs, the alarm fault code can be directly seen on the display, and can track the cause of the fault directly. The air pump can be started and stopped directly by touching the switch button on the display screen.

3. Any two of the micro vacuum pumps of the same model and version developed by Hilin Technology have good parameter consistency. In the closed circulation gas circuit, the design of the gas circuit is relatively complicated, and the damping is large, which leads to serious attenuation of the pressure and flow back to the original closed container. Use two sets of D series vacuum pumps and compressors of the same model and connect both to the same control electrical signal through the control circuit, two groups of approximately the same flow and pumping pressure can be obtained and the pressure in the container remains at a constant range (but in this plan, it is necessary to ensure that the specifications of the gas circuit connected between the two air pumps are the same, and the damping is similar; and the positive pressure value in the closed container cannot be greater than the maximum pumping pressure value of the selected micro vacuum pump in order to achieve this effect ).